Hydraulic motor: It is customary to refer to an energy conversion device that outputs rotary motion and converts hydraulic energy provided by a hydraulic pump into mechanical energy.

High-speed motor: The gear motor has the advantages of small size, light weight, simple structure, good manufacturability, insensitivity to oil pollution, impact resistance and low inertia. Disadvantages include greater torque ripple, lower efficiency, lower starting torque (only 60%-70% of rated torque) and poor low-speed stability.

model | ml/r | pressure(Mpa) | Rotating speed(r/min) | Output torqueN.m | Volumetric efficiency | Total efficiency | kg | ||

Rated | highest | Rated |

highest | ||||||

XM-F40L |

40 |

21 |

28 |

1500 |

2500 |

118 |

92 |

85 |

28 |

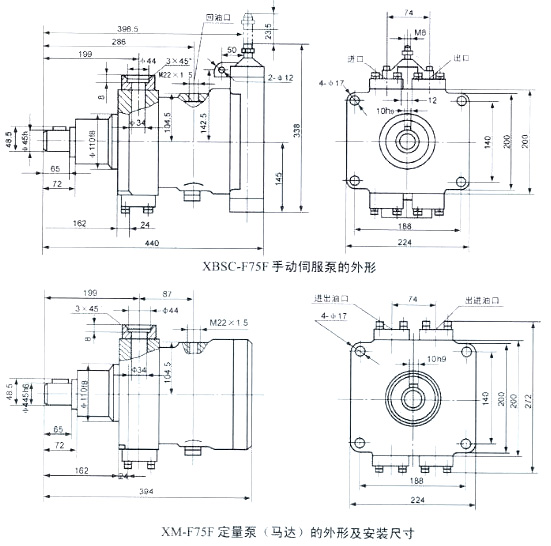

XM-F75F |

75 |

2000 |

225 |

60 | |||||

1. Working medium

(1) At ambient temperature above 15 degrees Celsius, N32, N46 machine tool hydraulic oil can be used, thickened 40-2 thickened hydraulic oil.

(2) At ambient temperature below 15 degrees Celsius, YH-10 aviation hydraulic oil (above -30 degrees Celsius) can be used, thickened 20-1 thickened hydraulic oil (above -5 degrees Celsius).

(3) In order to avoid abnormal wear of precision parts inside the motor, the motor oil inlet or return system is equipped with a precision oil filter with a filtration accuracy higher than 25 microns.

2. Installation

(1) Flexible couplings are used to connect the output end of the motor and the driven machinery. The coaxiality error of the two shafts is not more than 0.1mm. It is not allowed to use the transmission method of impact load such as chains and universal streets.

(2) It is not allowed to use the transmission method that makes the motor transmission bearing subject to radial force.

(3) The motor mounting bracket or base should have sufficient rigidity to prevent vibration and deformation from affecting the coaxiality.

(4) Strictly keep clean when installing pipelines and components. There must not be any dirt in the pipeline. The oil pipe used in the oil circuit must be subjected to a pressure test (recommended double the working pressure), and pickled and surface treated. After the pipeline is installed, use an auxiliary oil pump to pump circulating oil for flushing until there is no dirt in the filter, and then install the main oil pump for use.

(5) Pay attention to the steering of the transmission shaft to determine the connection mode of the inlet and outlet pipelines.

1. Working medium

(1) At ambient temperature above 15 degrees Celsius, N32, N46 machine tool hydraulic oil can be used, thickened 40-2 thickened hydraulic oil.

(2) At ambient temperature below 15 degrees Celsius, YH-10 aviation hydraulic oil (above -30 degrees Celsius) can be used, thickened 20-1 thickened hydraulic oil (above -5 degrees Celsius).

(3) In order to avoid abnormal wear of precision parts inside the motor, the motor oil inlet or return system is equipped with a precision oil filter with a filtration accuracy higher than 25 microns.

2. Installation

(1) Flexible couplings are used to connect the output end of the motor and the driven machinery. The coaxiality error of the two shafts is not more than 0.1mm. It is not allowed to use the transmission method of impact load such as chains and universal streets.

(2) It is not allowed to use the transmission method that makes the motor transmission bearing subject to radial force.

(3) The motor mounting bracket or base should have sufficient rigidity to prevent vibration and deformation from affecting the coaxiality.

(4) Strictly keep clean when installing pipelines and components. There must not be any dirt in the pipeline. The oil pipe used in the oil circuit must be subjected to a pressure test (recommended double the working pressure), and pickled and surface treated. After the pipeline is installed, use an auxiliary oil pump to pump circulating oil for flushing until there is no dirt in the filter, and then install the main oil pump for use.

(5) Pay attention to the steering of the transmission shaft to determine the connection mode of the inlet and outlet pipelines.

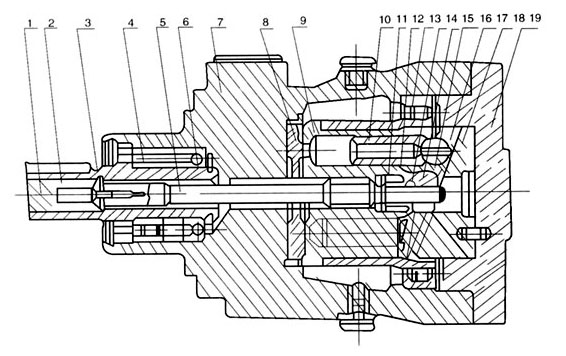

The outer shaft (3) of the motor is supported on the housing (7) with the bearings (4) (6). The inner shaft (5) is splined to the outer shaft at one end and splined to the cylinder (9) at the other end to start During no-load, the cylinder is kept in contact with the oil distribution plate (8) under the action of springs (2) and (11). The other end of the cylinder is supported on the housing with a bearing (13). 7 plungers (10), the spherical end of the plunger is locked with the ball socket of the sliding shoe (17). Usually, the sliding shoe is under pressure of the oil during operation to maintain a certain oil film contact with the swash plate (18), but when When the self-priming starts and the rotation speed suddenly increases, the sliding shoe may float. To prevent this phenomenon, the ball joint (15) at the end of the inner shaft, which is affected by the spring (11), bears the return disc and presses the sliding shoe against the swash plate. surface.

N = QP / (60η) (Kw) Actually used motor power

Q——Flow L / min (actual use flow)

P——pressure MPa (actual use pressure)

η——Total efficiency may be 0.85

The user can choose the motor after calculating according to the above formula according to the actual use load